Limited-slip differentials make it possible to avoid too great a difference in rotation between two axles, it can be those of the same axle (left and right wheels) or even. The aim is therefore to avoid having the perverse effect of a standard differential: if a wheel is relieved (it no longer has any grip on the road or very little) then it is the latter which will receive all the power. Indeed, a classic differential induces that the wheel which is braked the least / which has the least grip is the one which receives the most torque. Logically, the power (or rather the couple) passes by the easiest way.

To avoid this, we have made different systems which allow to make a kind of bridging between the two axes when the latter have a too high rotation differential, and for this there are several systems, let’s see the main ones. Note that some are used more for the central differentials (front / rear) and others for the same axle (left / right).

Torsen limited slip differential

It is one of the best known and most appreciated by lovers of fine mechanics. It is a question here of linking the two output shafts by sprockets, in such a way that it is then impossible to have a significant speed difference between the two shafts (the possible slippage is therefore limited between the two). The link is therefore permanent and it is physical. It cannot be modulated by electronics (apart from a little by playing on the brakes / ESP, but nothing on the differential side), the power is distributed in a natural way thanks to the gears.

It can be used as a central differential (ex: Quattro of old generation) as a differential on the front axle (ex: sports traction).

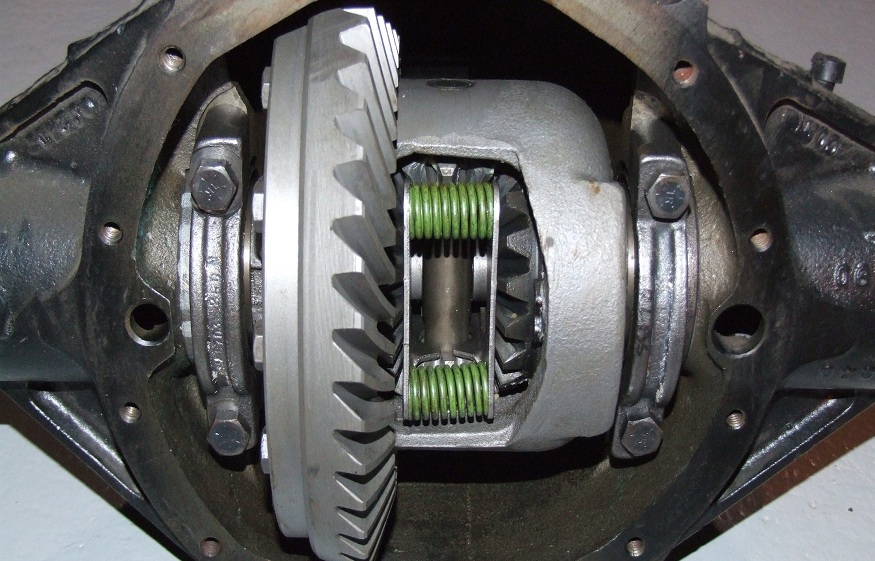

Crown-Gear / crown gears

Replacing the Torsen on the Quattro for a few years, this differential is just as mechanical and passive as the Torsen, no need to drive it. It is said to be asymmetrical because the maximum torque sent to the rear is not the same as that sent to the front (unlike the Torsen which is symmetrical). Here we can send a maximum of 85% to the rear or 70% to the front (values which are therefore not identical = asymmetrical).

Here the modulation between the front/rear distribution takes place via the green and red clutches (viscous coupling: engages on its own if overheating in the bell housing). Power comes from the motor through the purple axis which spins a crown (also purple). This crown is linked to the crowns of the front and rear axles by means of small sprockets (dark purple).

When one of the shafts races (loss of motricity) the multi-disc is used naturally and induces a solid connection between the engine and the rear axle.

Electronically controlled mechanical system

Each half-train is connected to the differential (which is classic by the way, ie “unlimited slip” if I can express myself in this way), we can then connect the wheel to the differential by engaging more or less the device of ‘clutch. Of course, a Haldex-style electro-hydraulic system is used here.